|

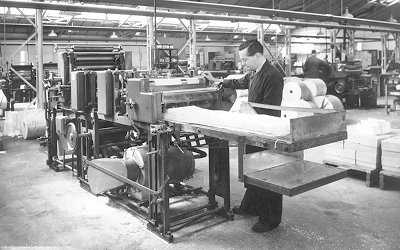

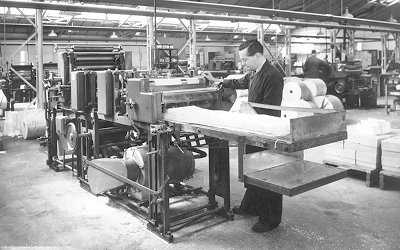

Right A very important part of Wilkes's business was business

stationery. This often involved producing documents in sets with

carbon paper between each set - so that, for example, a sales assistant

fills in the top white copy and thereby makes carbon copies on pink, blue

and green for different purposes within the company. Here a multiset

machine is set up to produce a six part document (one from each reel) with

five carbons in between. This was in the days before NCR paper. The

foreman making adjustments is Percy Cox. |  |

Right A guillotine used to trim paper to size and similar

work, either before or after printing. |

|

|

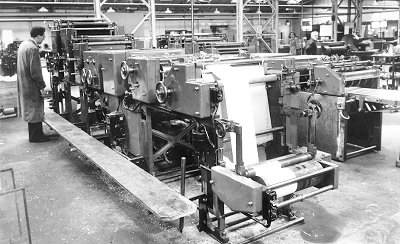

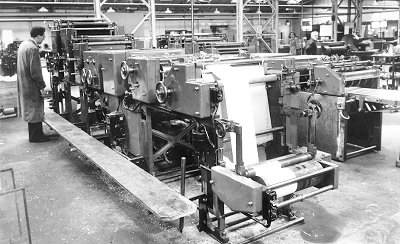

Left Printing to produce interfold paper. Continuous interfold enabled documents to be fed continuously into typewriters or other printers. Wilkes were early leaders in this field.

|

|

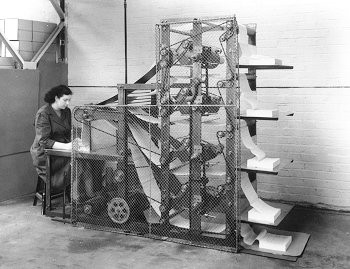

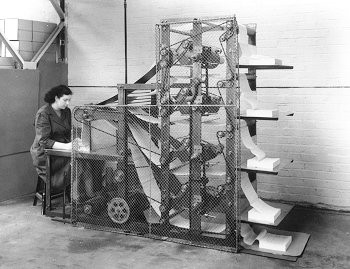

Left This is a pack-to-pack collating machine set up for 5

packs (in the trays on the right) and 4 carbons (on the reels in

the centre). When a job needed doing and there was no

machine on the market for doing it, then Wilkes manufactured

their own. This is such a machine, built at

Multimatic

Engineers, a division of James Wilkes. |

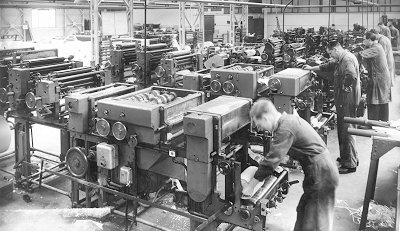

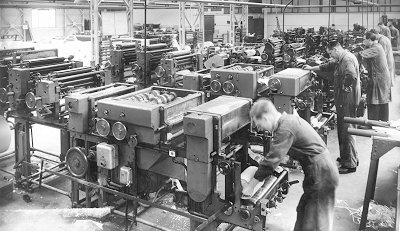

| Right Continuous stationery presses. When computers came along they used

this sort of continuous feed paper and Wilkes were among the first to

provide it - and computer stationery of all sorts. James Wilkes provided

sprocket punched continuous stationery to the English Electric Company for

use on its £50,000 "Deuce" computer. The computer was

used by Independent Television for their 1959 General Election coverage. |

|

Right A reel fed machine. The operator is Les Venvil. |  |

| Finishing processes such as manual collating, sewing,

punching and so on. |

|

And that finishes the trip round the works. | click here to go on with the

history of the company |