|

The British Heat Resisting Glass Company"Phoenix"

|

|

We now have further, and most valuable, information on Phoenix from David Encill. He found this material as part of his extensive research into the Chance Glass Works which has now been published as: "Chance Expressions: the History of Domestic Glassware from Chance Brothers", Cortex Designs, 2007". We are most grateful to him for providing us with all of this information and the pictures on this page.

David says that he believes that Col. Gell was a decorated World War One hero. But the earliest reference he has found to him at Chance comes in a patent filed on behalf of Chance Brothers, in 1926, which David records as follows:

CROOKES GLASS

Inventor: MARTIN HAROLD SHARPE; GELL PHILIP VICTOR WILLINGHAM; (+2)

Applicant: CHANCE BROTHERS AND COMPANY

EC: IPC:

Publication info: CA263966 - 1926-08-31

"Crookes Glass was a brand name used for spectacle and optical lenses, such as darkened lenses used for welding and sunglasses. I believe Chance also used this later when they stated producing spectacle lenses for the NHS, c.1948."

David has also come across two other patents involving Col. Gell, dated 1926 and 1927. All the patents assigned to him are concerning Crookes glass (named after Sir William Crooke, the inventor) "so his expertise was obviously related to optical glass".

These patents provide as with the full name of Col. Gell: PHILIP VICTOR WILLINGHAM GELL.

|

The cookbook is actually David Encill's mother’s and was sold or distributed along with Phoenix cookware. We are grateful to Mrs. Encill for letting us have these scans. |

|

David says that Chance first made their Orlak range (of heat resisting glass) in 1929 but sold it to James A Jobling (the makers of Pyrex) in 1933. Col. Gell, then with Chance, became disaffected by this sale and left to start Phoenix as a result. "The similarities between the two makes is quite remarkable, but probably not surprising: Orlak’s range included octagonal dishes (as well as circular and elliptical) and the handles were sunk into the lids, not unlike some of Phoenix. … Once Joblings had acquired the Orlak brand it was firmly buried but I doubt they ever expected Phoenix to arise from the ashes! That, of course, is almost certainly the reason for the name of the company".

David adds that he wonders sometimes whether Chance gave over to Gell the technology and expertise to enable the rivalry with Jobling to be maintained. I would add that this might have been part of the deal under which Gell left Chance.

The early Phoenix products were much close to Orlak than Pyrex in their design. "Gell would almost certainly have enticed Chance/Orlak workers to his new business and the designs would have utilised known good points. It would also have reflected the age, hence the modernist approach."

|

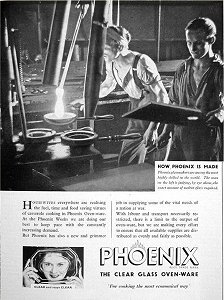

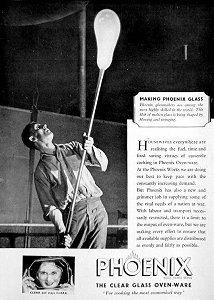

These adds, from the elegantly named Pottery Gazette and Glass Trade Review are 1935 and 1943. |

|

Something about the start of Phoenix can be seen in a 1935 press report (almost certainly based largely on a press release from Phoenix and a PR visit) which David has also supplied. The report says that they had earlier reported (apparently in the Autumn of 1934) that "a new organisation had been established in Lodge Road, Birmingham, for the specialised manufacture of a new brand of fire-proof glass bearing the distinctive mark of "Phoenix" glass." At that time production had not actually started. "We must frankly admit that we were rather impressed with the courage of the firm when, before their furnaces had actually got started last Summer, they were issuing broadcast a definite guarantee that they would be prepared to replace free of charge any piece of their oven glass which might fail, under fair conditions of oven use, within a period of twelve months". This, the press report says, has turned out to have been a guarantee that the company was "not unduly optimistic" to give. Oven breakage rates did not exceed 1% - "a really creditable result". By the time of this report deliveries of Phoenix wares had been going on for nearly six months. The report notes that "although this particular brand of glass possesses the yellowish tint which is inherent to all the true borosilicate high-resistances glasses, its tint is not unpleasant".

|

They also noticed that "dual

purpose articles are a feature of the productions and

the shapes really scientifically designed".

They add that the wares have handles in the form of bar sunken into the lid; and that this handle is made in the same mould as the rest of the piece and is therefore integral with it. This produces a very much stronger handle than could be produced by adding a knob of glass to an already formed piece. "To illustrate this we here reproduce a photograph of a full grown man suspended in a swing from the bar handle of a piece of ‘Phoenix’". |

David also has information on Phoenix’s closure: "British Heat Resisting Glass was taken over in 1968 by United Glass, which was the company producing the Ravenhead range of tumblers and glassware. The closure of Phoenix was announced in 1969, as it was proving unprofitable. The takeover may have been an asset-stripping operation by UG - possibly the value was seen in the property, rather than the plant. Of course, Phoenix might have finally closed its doors a little later, perhaps 1970".

A press statement published in Pottery Gazette and Glass Trade Review, June 1969 reads as follows:

Phoenix Factory to Close

The Bilston factory of British Heat Resisting Glass Co Ltd is to close. The directors of United Glass Ltd, have come to this decision following the loss of the " Phoenix " subsidiary in 1968. "During 1968 the marketing problems inherent in the Phoenix ovenware business of the British Heat Resisting Glass Co Ltd on the scale on which it was being conducted became increasingly apparent," says the annual statement. "The market share held by "Phoenix" is small and the cost of bringing this business to a reasonably profitable level would absorb a greater investment of money than would be justified by its potential."

James A. Jobling & Co Ltd are negotiating for the goodwill of the business and the stock but not the production facilities. If agreement is reached, Jobling Consumer Division say that they intend to use the " Phoenix " trade mark for new tableware ranges to be made at Wear Glass Works, Sunderland, and that the products are to be developed for new markets.

We know that Phoenix closed in Bilston but we do not know if Joblings ever actually acquired the Phoenix trade name, let alone used it.

click here to contine the Phoenix story |